The aftertreatment system in a commercial truck plays a critical role in reducing emissions and ensuring compliance with environmental regulations. As emissions standards have tightened over the years, manufacturers have developed advanced systems to minimize pollutants like nitrogen oxides (NOx) and particulate matter (PM). Understanding how these systems work and how to properly maintain them can help truck owners and fleet managers avoid costly repairs and downtime.

What Is an Aftertreatment System (ATS)?

The aftertreatment system is designed to clean exhaust gases before they are released into the environment. Unlike older diesel engines that emitted higher levels of pollutants, modern commercial trucks use aftertreatment technology to meet stringent EPA regulations. The system works by filtering and treating exhaust gases, reducing harmful emissions and improving overall engine efficiency.

Key Components of an Aftertreatment System

- Diesel Oxidation Catalyst (DOC): As the first component in the ATS, this helps oxidize carbon monoxide and unburned hydrocarbons into less harmful carbon dioxide and water, reducing the overall toxicity of the exhaust.

- Diesel Particulate Filter (DPF): The DPF captures and stores soot and particulate matter from the exhaust. Over time, the filter undergoes a regeneration process, where accumulated soot is burned off at high temperatures to prevent clogging.

- Selective Catalytic Reduction (SCR) System & Diesel Exhaust Fluid (DEF) Tank and Injector: The SCR system reduces nitrogen oxide emissions by injecting DEF into the exhaust stream, which then breaks it down into nitrogen and water vapor—both harmless to the environment. Maintaining the correct DEF levels and using high-quality DEF is essential for optimal system performance.

- Exhaust Gas Recirculation (EGR) System: While technically part of the engine, the EGR system helps reduce nitrogen oxide emissions by recirculating a portion of exhaust gases back into the engine, lowering combustion temperatures and minimizing nitrogen oxide formation.

Common Aftertreatment Issues and Aftertreatment System Maintenance

A well-maintained aftertreatment system ensures compliance with emissions regulations and prevents costly repairs. However, issues can still arise. Here are some common problems and maintenance tips to ensure the longevity and efficiency of your truck’s aftertreatment system:

- DPF Clogging: If the DPF does not regenerate properly, soot buildup can cause excessive backpressure, leading to poor engine performance. A forced regeneration may be necessary to clear the filter. Short trips and idling for long periods can prevent the DPF from reaching proper regeneration temperatures, so it’s best to avoid this and allow your truck to perform regular regeneration cycles.

- DEF Quality Issues: Using contaminated or poor-quality DEF can cause SCR system failures. Always purchase DEF from reputable suppliers, ensure it meets ISO 22241 standards, and store it properly to prevent contamination.

- Sensor Failures: Faulty nitrogen oxide sensors or pressure sensors can trigger warning lights and affect emissions control. Regular diagnostic checks can help identify sensor issues before they lead to bigger problems.

- EGR Valve Malfunction: Carbon buildup in the EGR valve can cause performance issues. Cleaning or replacing the valve as part of routine maintenance can prevent these problems.

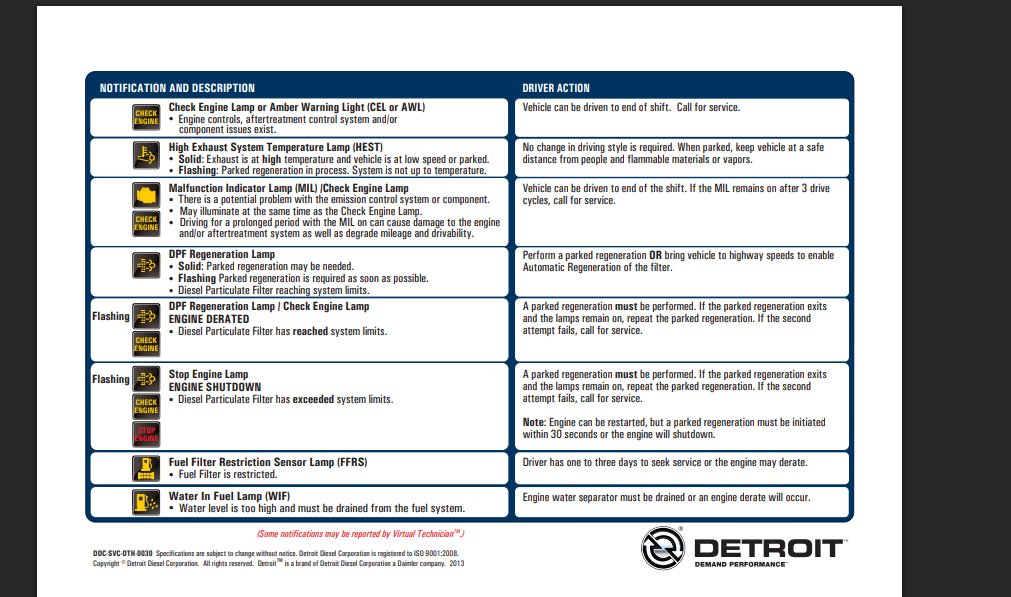

Lastly, as with any commercial vehicle, it is important to schedule routine maintenance inspections and monitor warning lights. With this ATS maintenance, any check engine or aftertreatment system warnings will be addressed, error codes and sensor issues will be checked, and potential leaks in the aftertreatment system will be identified.

Aftertreatment System Maintenance at Birmingham Freightliner & Western Star

The aftertreatment system in a commercial truck is essential for reducing emissions and keeping trucks compliant with environmental regulations. Proper maintenance and early troubleshooting can help truck owners and fleet managers avoid unexpected downtime and costly repairs. Birmingham Freightliner is here to help by conducting proper maintenance of your truck’s ATS system. Get in touch today to ensure your truck is running efficiently and is on the road for years to come.